Stainless steel Press plate

For PRESSING laminate board, PCB, CCL

HPL metal sheet supplier

HPL decorative metal serves as a type of aluminum decorative sheet for high-pressure laminate pressing.

To create the final HPL product, manufacturers apply glue to impregnated kraft papers and then press them with metal sheets, using the metal sheets as a decorative element instead of laminate decorative paper.

Apply HPL with decorative metal to the decoration of furniture, walls, kitchens, or cabinets. Its metallic texture on buildings creates a luxurious feeling.

Stainless steel Press plate

Melamine pressing decorative metal is also aluminum decorative sheets, but for Short cycle hot pressing as MDF, Partical board, Chipboard, for melamine hot pressing.

To make the final product, Metal MDF board or Metal chipboard, glue is applied to metal aluminum foil, which is then pressed onto MDF base board or chipboard base material. The metal is used as a decorative surface instead of laminate decorative paper.

MDF with decorative metal applied on decoration of furniture, walls, kitchen or cabinates. Decoration with metallic texture on building showing luxury feeling.

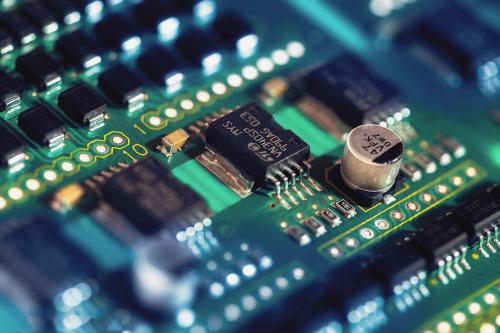

CCL stainless steel press plate

CCL stainless steel press plate is used for pressing Copper Clad Laminate. The process involves pressing glass fabric material and covering it with copper foil. The CCL then undergoes drilling, electroplating, wiring, welding prevention, and other processes before becoming a PCB.

Producing of CCL stainless steel press plate pressing require material with higher quality of surface smooth, flatness, and hardness, for long lifetime.

We have developed and improved of above specification for CCL press plate.

PCB stainless steel press plate

PCB stainless steel press plate is for pressing Printed circuit board.

To produce CCL, we first use hot and cold pressing to combine the copper foil and PP. Subsequently, to create PCB, we press the inner layer circuit, which is made from CCL, PP, and copper foil, together.

To put it simply, the circuit on the double-sided PCB is created from the copper on the CCL after design, going through the circuit manufacturing process (applying pressure film, exposure, development, and etching).

Laminate steel press plate

These plates are typically made of steel and are used in the pressing process to impart a specific texture or finish onto the surface of the laminate.

Application:

- Laminate Flooring: The press plate creates realistic textures that mimic natural materials like wood or stone.

- Furniture and Cabinetry: Adds decorative textures and finishes to furniture surfaces.

- Wall Panels and Countertops: Used to create durable and visually appealing surfaces.

How to use?

Product of Stainless steel Press plate, is used for laminate pressing. Final product is furnitures.

Require high pressure laminate machine for HPL, or Short hot press machine for melamine pressing MDF, Chipboard.

Pressing the materials to make HPL with decorative metal, or MDF with decorative metal. Application for furnitures, Kitchen boards, Cabinet, doors and etc.

What we have?

We have developed hundreds desings and colors for melamine pressing aluminum sheets, which applied on HPL, MDF or Chipboard.

For quality control during production, we utilize an automatic anodizing production line, roll anodizing production line, color-coated aluminum lines, brushed melamine pressing aluminum foil production line, mirror aluminum production line, and other equipment for processing melamine pressing aluminum decorative foil products. Our current annual output is 50,000 tons, and we are continuously expanding our capacity.

We have beeing producing of Metal products over 20 years, and experience of aluminum decorative sheets over 10 years, besides, we developed PCB press plate, and CCL press plate over 5years to impove current market stainless steel shortage to match higher quality standard.

Application of melamine pressing decorative sheets for furniture laminates, PCB press plate and CCL press plate for electronic products.

ZORI

How to use?

Product of Melamine pressing aluminum sheets, is used for laminate pressing. Final product is furnitures.

Require high pressure laminate machine for HPL, or Short hot press machine for melamine pressing MDF, Chipboard.

Pressing the materials to make HPL with decorative metal, or MDF with decorative metal. Application for furnitures, Kitchen boards, Cabinet, doors and etc.